The Permian Basin, America’s strategic energy resource, has demonstrated its strength and resilience despite unprecedented challenges not faced by producers in other nations. It’s a testament to the commitment, dedication, and professionalism of the operators in the Permian, benefitting American consumers, industries, and investors. Given the pandemic, a war in eastern Europe, and tension with our allies, energy security and independence remain as important as ever. If there is any doubt, look at the problems now facing the European Union.

The Permian is the largest oil producing province in the world’s leading producing nation. U.S. oil production is fast approaching pre-pandemic levels — led by the Permian — with roughly half of the operating horizontal rigs in the nation. This robust recovery has occurred despite numerous challenges, including supply chain disruptions in materials and frac fleets, inflationary cost increases, workforce turnover during the pandemic, investor demands for returns over reinvestment, and increasing federal, state, and investor pressure in environmental performance.

Demands for improvement in environmental performance, notably flaring and methane emission reduction, is coming from multiple directions at the same time. The U.S. EPA is formulating new rules for the upstream industry under the Clean Air Act and has further designated certain counties in the Permian as exceeding ozone standards (ozone can be formed by hydrocarbon emissions and nitrogen oxides in the presence of sunlight).

The State of New Mexico is already formulating its plan for reducing these emissions. The advent of ESG is also having its impact on the industry, and some states are objecting to the use of ESG scoring by credit rating agencies and resisting ESG pressures from institutional investors. Yet, many operators have adopted their own ESG standards and are now providing sustainability metrics and reporting their improvements in environmental performance. While the need for improvement may seem obvious, it requires changes in operating practices, additional investment, and an adjustment in the culture of the company and its people – never simple tasks.

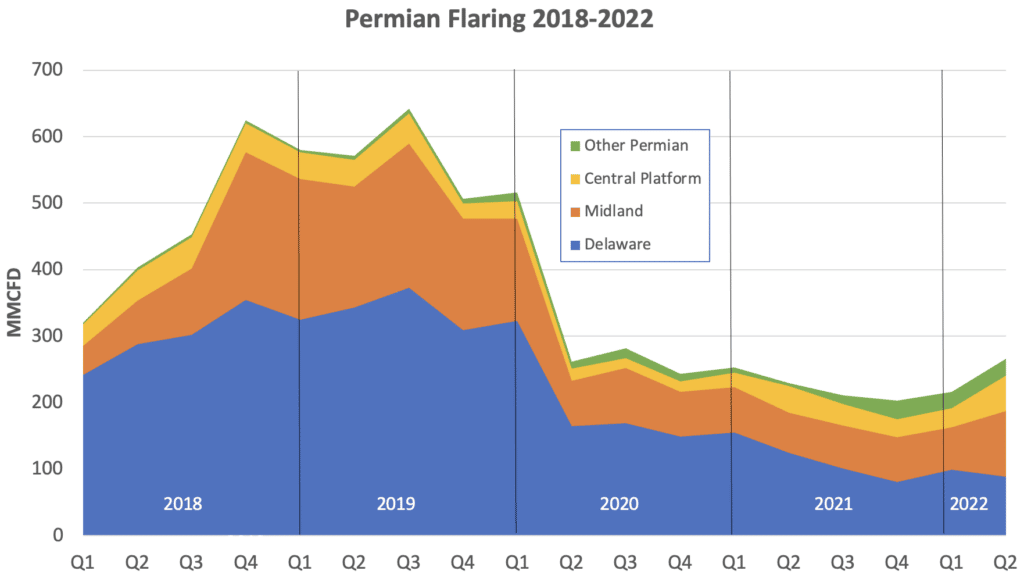

The chart below shows flaring in the Permian since 2018, where flaring and associated and tank gas has roughly halved over the five year period. Much of this progress is due to the addition of new gas pipeline capacity in the basin, but operators have also begun to defer initial oil production until gas take-away capacity is available. Nevertheless, continuing to flare over 250 MMCFD is a significant loss of an energy resource and equally significant contributor to emissions and GHGs. The rate of flaring in the second quarter of 2022 (i.e., 266 MMCFD) would supply nearly one-half of the gas used by residential households in Texas, based on data for the year 2021 provided by the U.S. Energy Information Administration.

Source: Rystad Energy

EcoVapor has been engaged in helping operators reduce emissions from tank batteries, with technology that significantly reduces the likelihood of venting from tanks as well as gas treating solutions that allow an operator to sell tank gas instead of flaring. Nationwide, EcoVapor’s solutions have helped operators reduce CO2e emissions by several million metric tonnes each year, and numerous Permian operators — from small independents to major operators — have deployed EcoVapor technology at their production sites. This equipment includes systems to manage tank pressures to avoid venting, gas treating for contaminants such as oxygen and hydrogen sulfide so the gas can be sold instead of flared, trailer-mounted versions of this equipment for temporary needs such as tank cleaning, and diagnostic tools to help an operator understand the conditions at their tank batteries as a part of developing an effective solution.

We are proud to count these environmentally responsible companies as a part of our client base and to support them in achieving their objectives.